G28 Safety home, incase you forgot after power on. Header M106 P0 S255 This line is spit out by Luban and Snapmaker settings in Lightburn, so I include it.

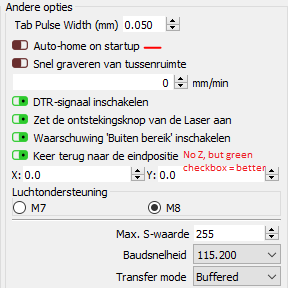

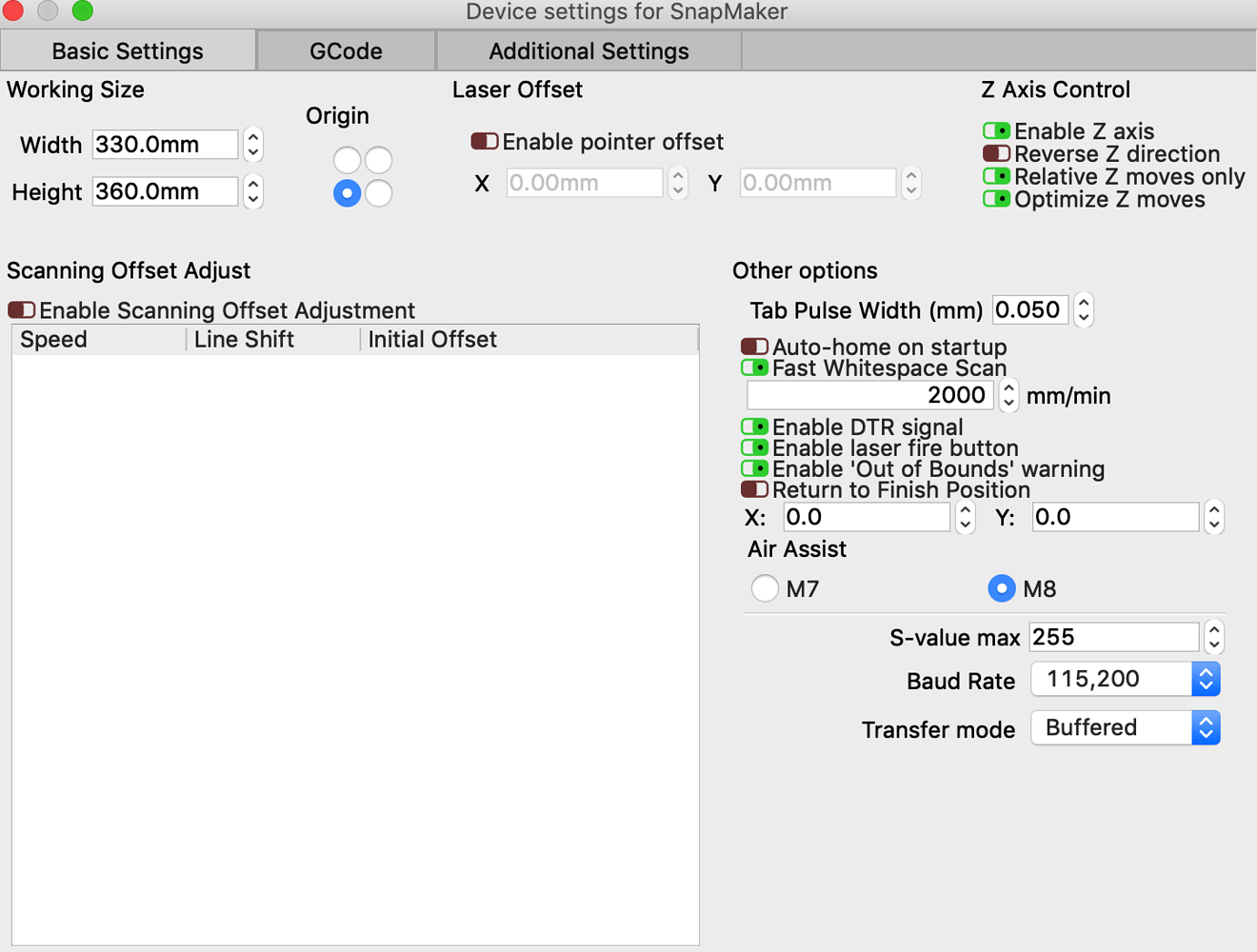

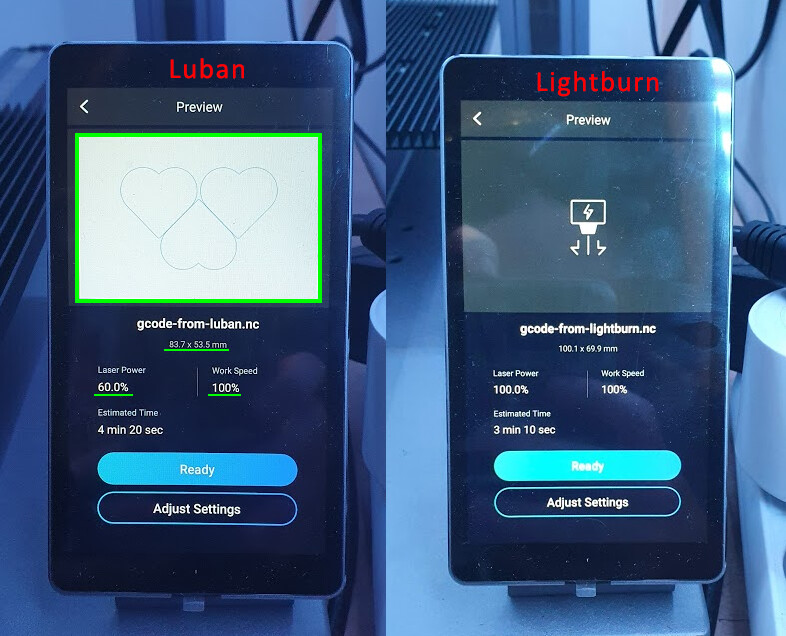

The other settings you can change as you need, but ensure S-value max is set to 255. In the Basic Settings tab, tick Enable Z axis but untick Relative Z moves only. Now after setting your machine as the type it certainly is not, open the device settings, there’s a few specific things we need to do. Selecting GRBL-M3 solves a few problems with using Marlin as the machine type (mostly how it turns the laser on/off, and had required some minor gcode edits before being ran). If not, add the machine new.Īfterwards, it’s mostly normal, except uncheck the “auto home” during device setup. If you already have your snapmaker setup in Lightburn, you can click devices > select your machine > edit. Now here’s the special part, you need to setup your machine type as GRBL-M3 instead of Snapmaker or Marlin. To start, you require… LIGHTBURN imagine that, a guide that specifically states a software, you need it. I know, I know, enough of the fluff, get to the guide! It’s rather simple, so this guide is not going to be in the standard tier system of my other guides, mostly infographic style with a few pictures. This requires Lightburn, however, and is not currently a feature of Luban. This enables inline features to the Marlin firmware, allowing you to use dithering without the stop/go stutter that stock does, as well as true grayscale, which varies the power of the laser to create gradients. Make sure to update your machine and modules to the latest official firmware, then unzip my firmware to your USB drive and flash it. This is modified and compiled by me and is what I use on both of my machines, an F350 with 10W laser, and A350 with 1.6W laser. The above is the latest (as of writing this guide) version of snapmaker firmware. So here is the warning, I’m not liable for any damage to your machine, material, fire, or loss of sanity. This is NOT in the private releases (the ones supplied by Snapmaker directly) so you WILL have to load a ‘custom’ firmware. To start! This does rely on the inline control that’s been incorporated in the public github version of the firmware. It should be the same pretty much, just it can measure your material itself. However, I’ll also be putting notes that SHOULD work (EDIT: spoiler, it does) with the 10W, which I have, I just haven’t tested yet. I’ll be posting the setup I use for my A350 with the original 1.6W laser. As always, feel free to ask questions and I’ll try filling in any gaps you find. Letting you skip Luban or using the USB drive entirely.Ī quick note, this guide, like most of mine, will assume you have some experience with the machine. This guide will allow you to do your entire project in Lightburn, and (if connected via USB) run it directly from Lightburn.

It’s been awhile since I’ve done a guide, and this one was a long time coming.

0 kommentar(er)

0 kommentar(er)